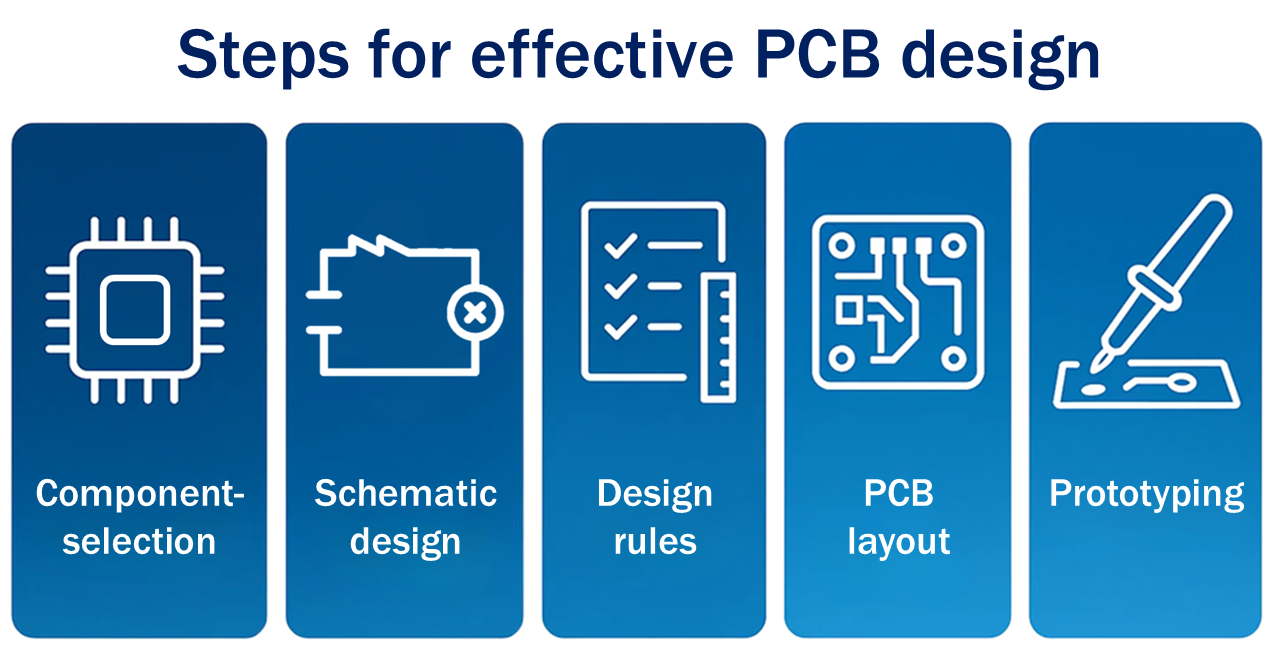

Designing reliable PCBs starts with deliberate choices: component selection and derating, early stack-up definition and disciplined layout. This article shares the practical principles that have the biggest impact in the lab and in production.

Whether you build a simple sensor board or a power-dense converter with strict EMI requirements, the same fundamentals apply. Let's go step by step so you can reach robust, repeatable results faster.

Why reliability matters

Reliability doesn't just determine the total cost of a project—it also affects warranty claims, user experience, and your company's reputation. A PCB that fails prematurely can lead to costly recalls, customer dissatisfaction, and legal issues. That's why it's crucial to design from the start with lifetime, temperature, and environment in mind.

In my experience, most PCB problems can be prevented through early attention to component selection, thermal management, and robust design principles. It's much more cost-effective to invest extra time in the design phase than to have expensive iterations and production adjustments later.

Component selection and derating: the foundation of reliability

Component selection forms the foundation of a reliable PCB. This goes far beyond just selecting the right values—it requires a deep understanding of how components perform under different conditions. I always work with thermal margins, voltage/current derating, tolerances, and availability as starting points.

Thermal aspects

- Use datasheet derating curves with realistic ambient temperatures

- Calculate thermal resistance (Rth) for worst-case scenarios

- Spread dissipation across multiple components where possible

- Consider thermal cycling and aging effects

Electrical aspects

- Analyze and protect against voltage spikes (inrush, transients)

- Check DC-bias loss in capacitors

- Respect SOA (Safe Operating Area) for MOSFETs/diodes

- Add protection circuits where needed

A practical example: when selecting a MOSFET for a switching power supply, I check not only the nominal currents but also inrush currents, thermal cycling, and the impact of fast switching transients. This has saved me from component failures in production multiple times.

Schematic design and PCB stack-up: laying the foundation

Schematic design and PCB stack-up are closely connected and largely determine the performance of your end product. In schematic design, I always start with proven reference designs but add protection circuits like TVS diodes, snubber circuits, fuses, and reverse protection. The system must be fault-tolerant and contain sufficient test points for debugging and production testing.

Stack-up definition is crucial and must be locked down early in the process. I always define the FR-4 class/Tg, copper thickness, impedance control, and return planes before starting the layout. This determines not only signal integrity and power integrity but also EMI performance and thermal behavior of the PCB. A wrong stack-up choice cannot be corrected later without a completely new PCB.

Layout principles and EMI/EMC: the art of placement

The layout phase is where all theoretical knowledge is converted into practical results. These principles have the most effect on reliability and performance, so focus here for maximum impact with minimal effort. It's not just about placing components nicely, but about creating a robust system that functions reliably for years.

Current and return paths

Design for short, controlled returns with solid ground planes. Avoid long, narrow traces for high currents.

Decoupling

Close to pins, right ESR/ESL; short and multiple vias. Different frequencies require different capacitances.

Thermal

Thermal vias, copper polygons, spread dissipation and avoid hotspots. Temperature differences cause mechanical stress.

Creepage/clearance

Respect standards for mains voltage and critical paths. Safety comes first.

EMI/EMC must be considered from day one in the design. Minimize loop areas through careful placement of components and traces, use proper terminations for high-speed signals, implement filters where needed, and develop a thoughtful ground strategy. Separate analog, digital, and power domains where possible—this prevents cross-interference and makes debugging much easier.

Power Integrity and Signal Integrity are closely connected to layout choices. Design your PDN (Power Distribution Network) with sufficiently low impedance across the entire frequency spectrum. Prevent ringing and overshoot through proper terminations and layout speed control. A well-designed PDN is often the difference between a PCB that works and one that works reliably under all conditions.

DFM/DFT and prototype validation: from design to production

Design for Manufacturing (DFM) and Design for Test (DFT) are often underappreciated aspects of PCB design, but they make the difference between a prototype that works and a product that can be reliably manufactured. These principles ensure efficient production and reliable quality control, ultimately resulting in lower costs and higher quality.

Design Rules

Honor assembly and design rules: clearances, solder mask, paste apertures. Work with your assembler for optimal rules.

Panelization

Plan panelization, fiducials and tooling holes for efficient production. Optimize for minimal waste and maximum throughput.

Test Points

Add test points for AOI/ICT and functional tests during production. Testability is crucial for quality control.

The prototype phase is where theory and practice come together. Always run thorough ERC/DRC before going to production, test under worst-case conditions and log all measurement data systematically. Consider simulation for high‑speed/power where it pays off—this can save a lot of time and money in later phases. A well-tested prototype is the foundation for a successful product.

Real-world examples

Want to see concrete examples? Explore PCB projects on the projects page where these principles are applied in practice.

Common pitfalls and quick wins

After years of PCB design, I've seen certain patterns that keep recurring. These common mistakes not only cost time and money but can also lead to production problems and customer dissatisfaction. Here are the most frequent pitfalls and how to avoid them:

- No defined return path: This introduces EMI problems and measurement issues. Always ensure a continuous, low-impedance return path.

- Insufficient or poorly placed decoupling: This causes power integrity problems and instability. Place decoupling close to every IC pin.

- Via-in-pad without proper filling: This leads to solder problems and mechanical weaknesses. Use via-in-pad only where necessary and fill them properly.

- No thermal path for power components: This causes overheating and premature failure. Thermal pads are essential for power components.

- Stack-up missing continuous reference planes: This causes signal integrity problems. Plan your stack-up carefully for continuous reference planes.

The quickest wins come from paying attention to these basic principles. It takes little extra time to do them right, but saves enormous time and money in later project phases.

Checklist before production

- Derating checked (T, V, I) for all critical parts

- Stack-up locked with impedances and copper thicknesses

- Decoupling per IC reviewed (value, ESR/ESL, placement, vias)

- Return paths and reference planes continuous and short

- EMC: filters/terminations and domain separation

- PI/SI: critical nets reviewed/simulated when needed

- DFM/DFT: clearances, test points, fiducials, panel

- DRC/ERC clean; bring-up points and plan in place

Conclusion

Reliability is the result of early decisions and consistent execution. By steering component selection, stack-up, layout and test from day one, you build boards that perform predictably and are easy to manufacture.

Need a second set of eyes on your PCB design, or help taking a concept to production? Get in touch.