SCD30 Address Board PCB

Custom address board for SCD30 CO₂ sensors: Modbus RTU address translation via DIP-switch, robust RS‑485 hardware and industrial firmware. Fully developed by me: hardware and firmware.

Project Description

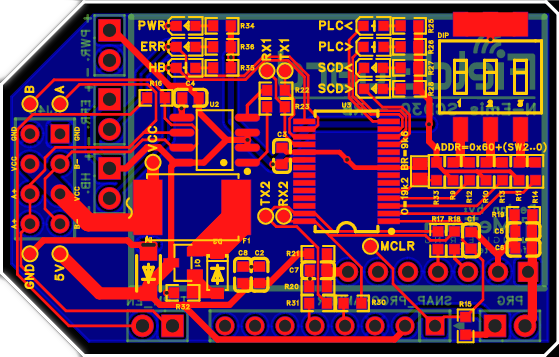

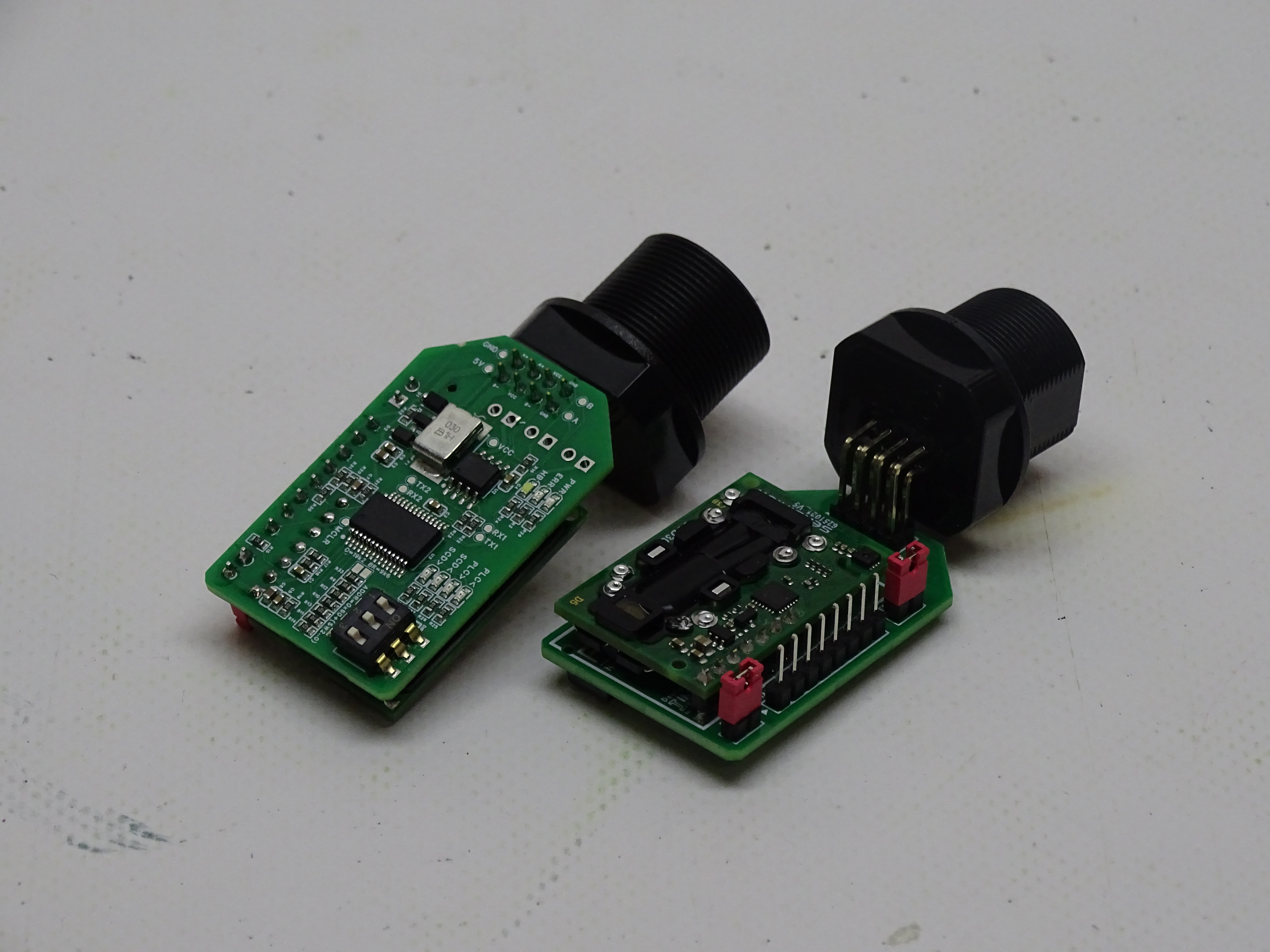

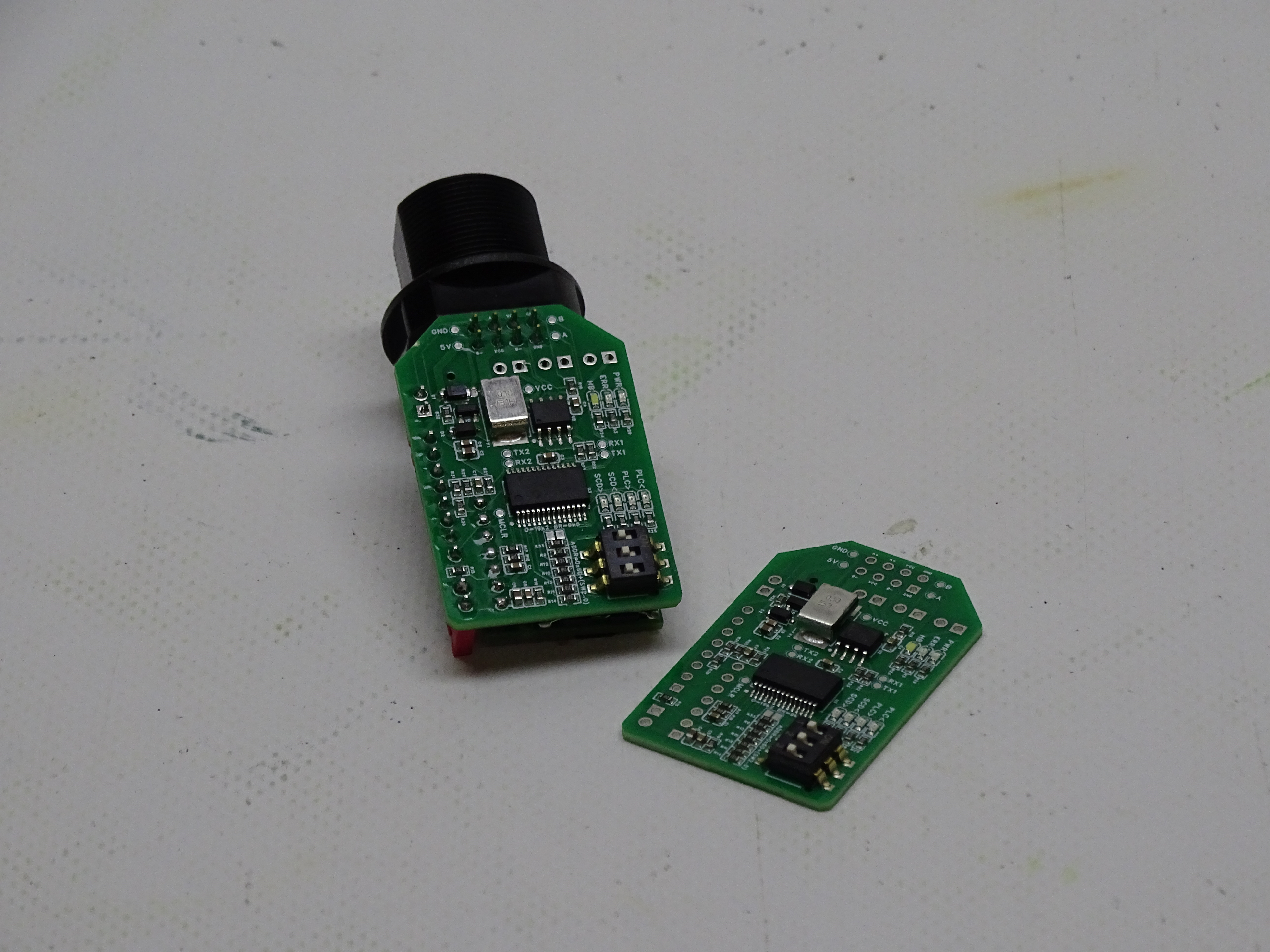

The SCD30 Address Board PCB is a compact interface board that enables multiple SCD30 CO₂ sensors on a single Modbus RTU bus. Using a DIP-switch, each sensor is assigned a unique address (0x60–0x67), making integration and daisy chaining straightforward and scalable.

The hardware features a low-power microcontroller and a robust RS‑485 transceiver. The design includes overvoltage protection, reverse polarity protection, configurable termination and bias resistors, plus bus in/out connectors for daisy chaining. This board is specifically developed to enable robust long distance Modbus RTU communication, making it robust for industrial environments.

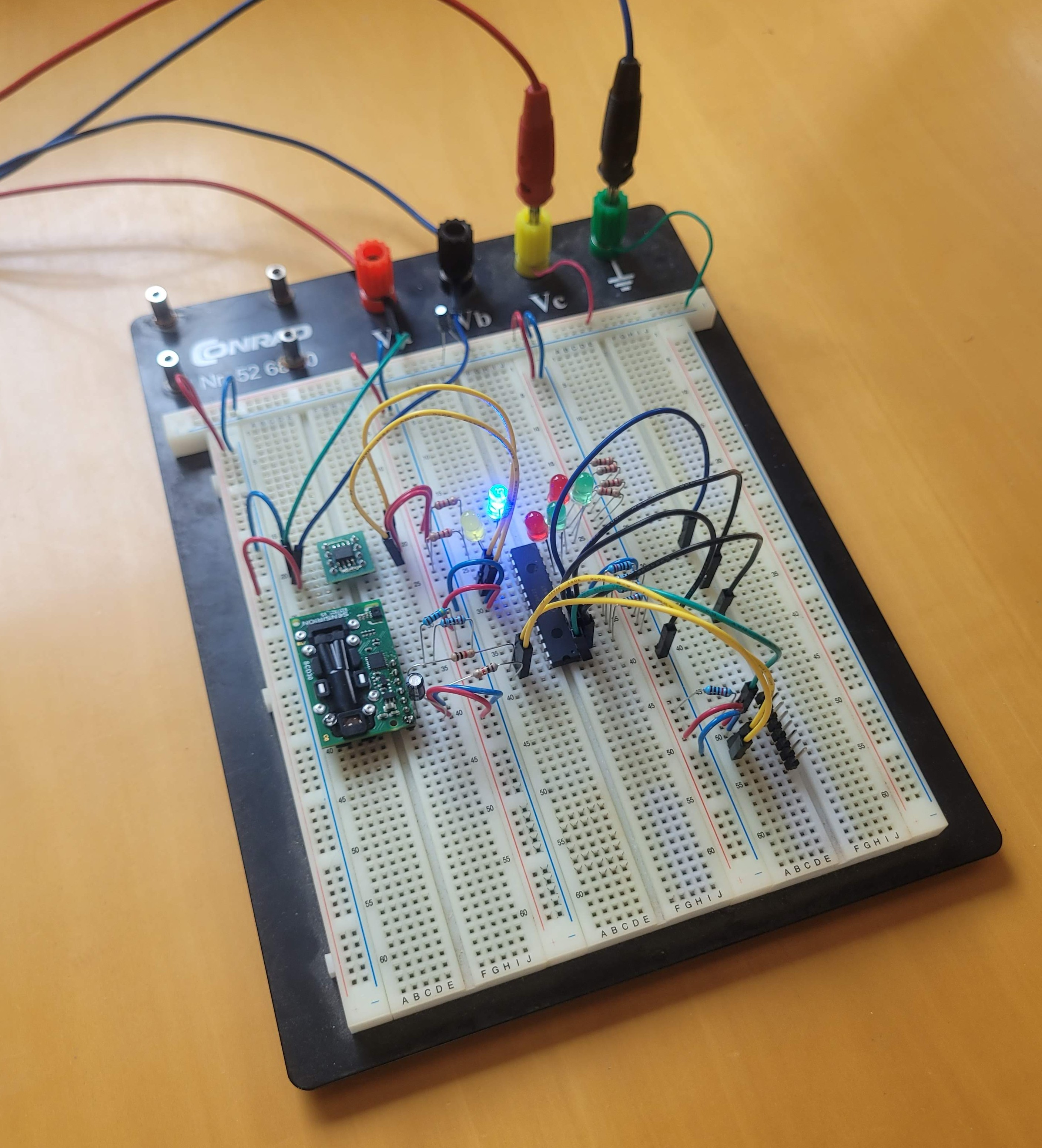

The development process progressed from a breadboard prototype (proof of concept for Modbus handling, address translation and error checking) to a production‑ready PCB design and final assembly. The first image shows the prototype; the following images show the final design.

The firmware is fully developed in C and implements Modbus RTU handling, address translation and extensive error checking. A status LED reports 14 fault codes (including CRC errors, busy, timeout, illegal function, address mismatch), enabling quick on-site diagnostics. The system is designed for stable 24/7 operation in sensor networks.

I developed this project end-to-end: both the hardware design (schematic, PCB layout, protections) and the firmware (Modbus stack, state machines, error handling). The result is a low-maintenance, scalable solution for CO₂ monitoring.